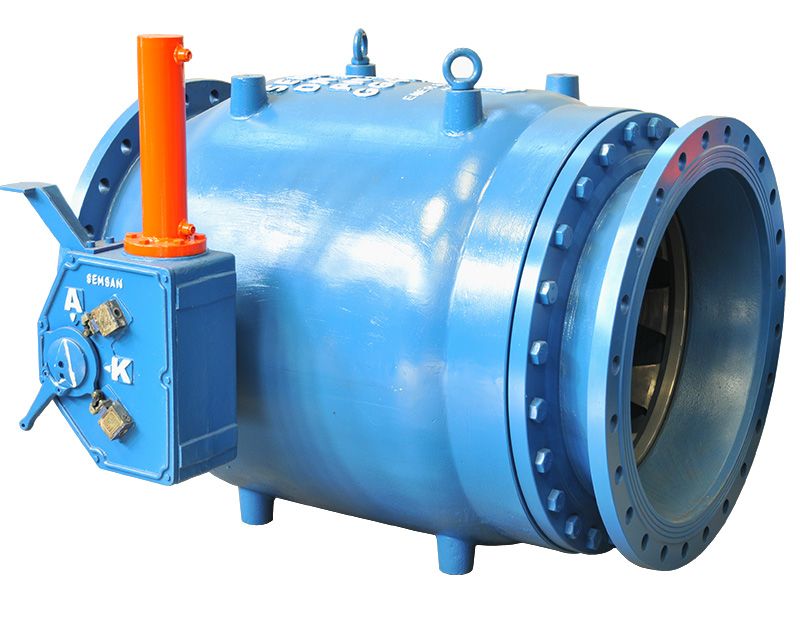

PLUNGER VALVE DN 150/1400 | PN 10/ 16/ 25/ 40/ 64

Application

- Open – Close valve for high presure and flow velocity

- Pump Control Valve

- Water Level Control Valve

- Bottom Outlet Valve

- Turbine Inlet and Turbine By – Pass Valve

- Pressure Control Valve for Drinking Water

- Flow Rate Regulation Valve

- Pressure Control for Irrigation Projects

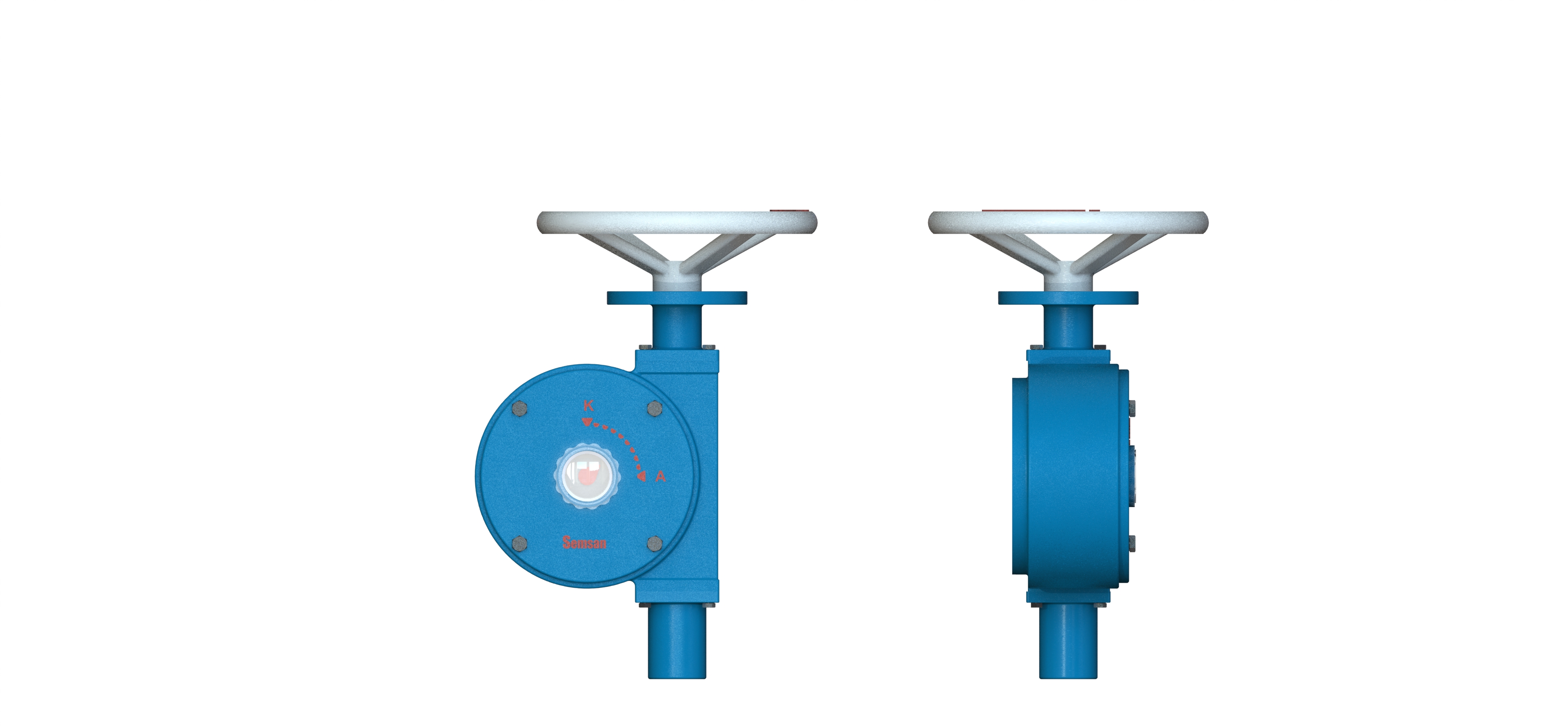

Control

- Handwheell

- Electrical Actuator

- Pneumatic Actuator

- Hydraulic Actuator

- On-off or Modulating Operation

Catalogs

Technical Datas

Cad Files

LAST QUALITY CONTROL EN 12266 – 1 CLASS A

| Nominal Diameter | Nominal Pressure PN |

Test Pressure | Max Pressure for Temprature |

|

|---|---|---|---|---|

| (DN) | kg/cm2 | Body | Disk | 50 °C |

| 150.....1400 | 10 | 15 | 15 | 10 |

| 150.....1400 | 16 | 24 | 24 | 16 |

| 150.....1400 | 25 | 37,5 | 27,5 | 25 |

| 150.....1400 | 40 | 60 | 44 | 40 |

| 150.....1400 | 64 | 96 | 71 | 64 |

ADVANTAGES

- Pressure, flow rate and water level control valve

- Low operation torques on high pressure diferences

- High safety coefficient design

- Lineer regulation capability

- Suitable for modulating operation

- Low cavitation risk

- Metal seaing, additional EPDM seal ring

- Special outlet design for project.

- Operation types for application areas

- Low maintenance cost

DESIGN

- TS EN 593 Certificated

- PN10 – PN64

- Double Flange

- Face to Face EN 558 – 1 Series 15 (up to DN500 1,5 x DN)

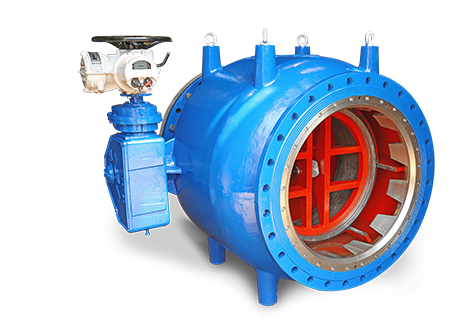

- Open Close and Control Valve

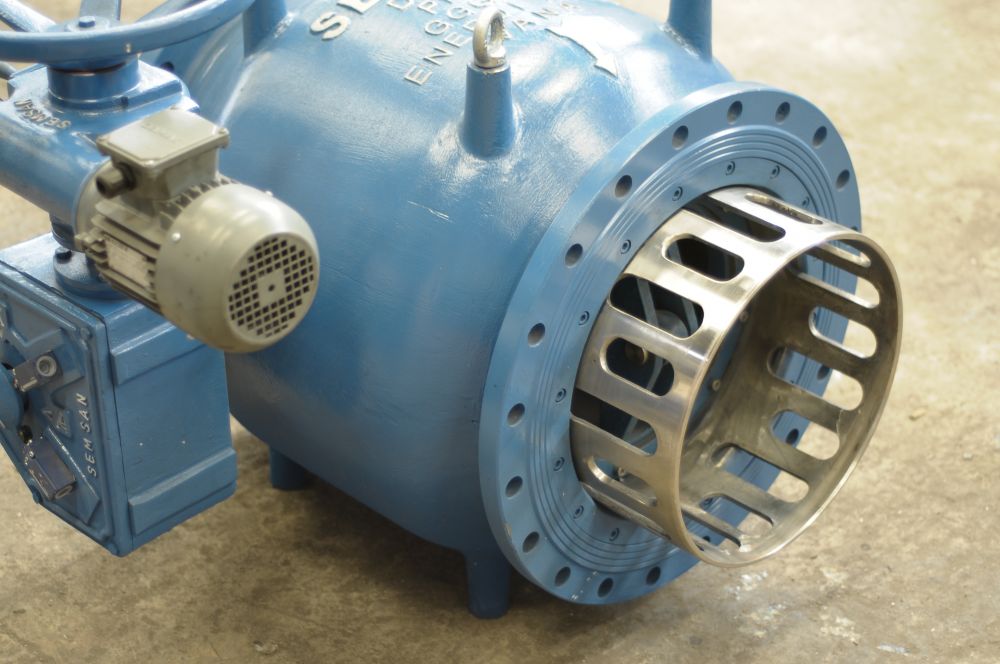

- Axial Movement for Plunger

- Rotationally Symetric Flow

- Metal seaing, additional EPDM seal ring

- Adjustable and Replaceable Sealing Ring

- Mechanical position indicator and limit stops on gear box

- Max Operation Temperature 50°C

- Movement Parts are Stainless Steel

CORROSION PROTECTION

- Electrostatic Powder Coating for Drinking Water

- Zinch – Rich Epoxy Primer

- Coal – Tar Epoxy

- Glass Flake Epoxy

- Enamel Epoxy for Ultraviolet

- Completely Stainless Steel Design

- Ebonite Coating for Seawaater

Part List

| PART NAME | MATERIAL LIST | |

|---|---|---|

| 1 | Body | GJS 400-15 / GJS 500-7 / Stainless Steel |

| 2 | Piston (Plunger) | Stainless Steel |

| 3 | Sealing Ring | Flange Stainless Steel |

| 4 | Bolts and Nuts | Stainless Steel |

| 5 | Sealing Ring | EPDM + Metal Sealing |

| 6 | Cranck Mechanism | Stainless Steel |

| 7 | Valve Shaft | AISI 420 (X20Cr13) Stainless Steel |

| 8 | Bearing | GBzSn (Bronze) |

| 9 | Gear Boxes | GJS 400-15 / GJS 500-7 |

Valve Dimensions

Flange Dimensions

Gearbox Dimensions